QIDI Q1 Pro: A New Choice for Affordable 3D Printer

Following the success of the QIDI Smart3, Plus3, and Max3, QIDI Tech is back in 2024 with the Q1 Pro, the first consumer 3D printer with active chamber heating available.

The QIDI Tech R&D team, renowned for its commitment to excellence, continues to push the boundaries of FDM 3D printing technology. The newest FDM 3D printer, Q1 Pro, adds additional capabilities to the lineup of last year’s flagship device, MAX3. While MAX3 sets the pace with its high-speed capabilities, expansive build area, and versatile material compatibility thanks to active chamber heating, Q1 Pro goes even further.

Speed and quality have emerged as the primary factors for determining if a consumer-grade 3D printer is up to the task. QIDI Q1 Pro stands out as a high-speed 3D printer due to its impressive print speeds of up to 600mm/s, coupled with an acceleration rate reaching 20,000mm/s². This performance does not come at the expense of precision or quality. The machine also includes fully automatic leveling with dual sensors, dual Z-axis motor drives, bimetallic nozzles, and a revolutionary active heated chamber system, all of which significantly increase print quality. Additional functions extend to vibration correction, power failure replacement, material break/tangle detection, and remote monitoring to improve the user experience.

Basic Functionality Upgraded

QIDI Q1 Pro arrives ready to use, straight from the box. Simply remove the packing materials — tape, ties, and screws — that secure it during shipping, and you’re ready to power it up and start printing.

Like its predecessors released in 2023, the Q1 Pro keeps using the Core-XY motion mechanism which is thought to be optimal for quick printing. The internal structure is an all-metal frame, reinforced with a metal crossbar at the base for added stability. The XY axis is a 10mm hollow optical axis, which is employed in most machines to minimize weight. Unique to the Q1 Pro is its twin Z-axis design. The Z-axis movement is controlled by two independent motors to assure the machine’s stability, and it includes an auto-tilt leveling function to avoid discrepancies in left and right heights produced by lengthy operations.

The QIDI Q1 Pro is entirely enclosed and has a separate heater for active heating which maintains the chamber temperature at a steady 60°C. This not only lowers print distortion but also improves adhesion between the model’s layers, preventing delamination. When combined with a hot bed heated to a maximum of 120°, this is quite useful for printing warp-prone materials like ABS and PA. This unique design increases print success rates while also improving print quality.

The Q1 Pro utilizes a proximal dual gear direct drive extruder design with a 9.5 to 1 gear ratio to ensure efficient power transfer for fast, accurate and stable consumable feeding. This is critical for performing high-speed 3D printing. Unlike the previous QIDI X series which came with two sets of hot ends randomly, the Q1 Pro defaults to a 0.4mm bimetallic nozzle with a stainless steel outer layer and a hardened steel tip, capable of enduring temperatures of up to 350°C. Such durability and thermal resilience make it versatile for handling a wide range of printing materials, freeing users from the constraints of material compatibility.

The Q1 Pro excels at printing with high-temperature engineering materials. We invited experienced Redditors to test the printer to authenticate its capabilities:

“We selected a tower model from the randomly supplied models and used PLA-CF. It took 4 hours and 24 minutes, and the quality of the print was outstanding.

We then printed models of current fashions, including a retractable sword, a skeletonized ping pong ball, and a movable swallow. The prints all came out in one go and the results were quite impressive. The only small problem was that the ping pong ball had a more pronounced pulling phenomenon due to the high number of retractions, but this can be solved by optimizing the print parameters.

We expanded our testing to include PETG, ABS, ASA, and PLA filaments to assess the Q1 Pro’s versatility with different materials.

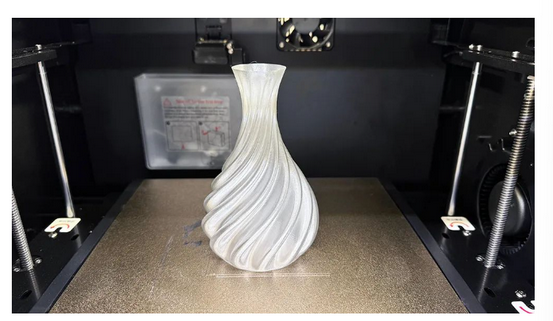

Starting with PETG, we chose a vase model and utilized the ‘spiral vase’ mode available in the slicing software. The print settings were fine-tuned for a 0.5 mm line width and a solid foundation of 5 bottom layers. Although the overall print was successful, we noticed that the vase exhibited minor leakage. This issue might be attributed to tiny gaps within the print or indicates that further optimization of print parameters is needed to achieve a watertight result.

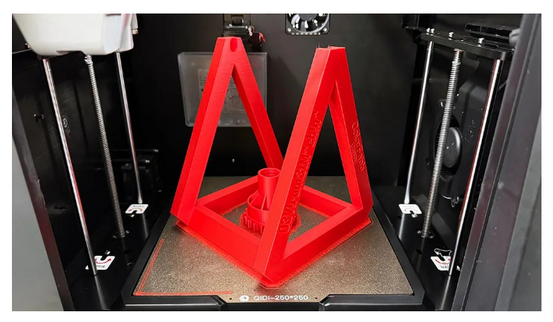

Next, our testing involved printing filament holders using ABS filament. Although the original consumable extension holders were more than adequate, we chose to print one to place on the side of the machine to make it easier to access the filament. Upon inspection of the printed holder’s base, it was apparent that there were no warped edges or signs of layer separation. Such precision in the print quality can be attributed to the active chamber heating of the printer.

Finally, we assessed the Q1 Pro’s batch printing capabilities by printing 39 whistles in a single comprehensive PLA filament run. The final product was also molded in a single pass, with no “scrambled” surfaces. This test also proved that Q1 Pro is suited to the daily needs of 3D printing farmers, and the machine is stable enough.”

Newly Upgraded Features of the Q1 Pro:

Filament Run-out Detection: The Q1 Pro is enhanced with an auxiliary filament sensor above the extruder gear. When the filament runs out or a break occurs during printing, the machine will automatically stop printing, effectively avoiding wasting. The front cover of the print head is fitted with a 5015 radial fan for part cooling, which is secured by two plastic clips and magnets in the housing, making it both robust and easy to remove and maintain.

Filament Tangle Detection: It is worth mentioning that the Q1 Pro has also been upgraded with a Filament Tangle Detection, realized by a sensor located on the back side of the machine’s chamber. During the printing process, if the material cannot be fed properly due to a tangle, the machine is able to quickly recognize the problem and automatically pause the printing, as well as send out an error alert.

Nozzle Wiping Mechanism: Interestingly, the Q1 Pro is equipped with a nozzle wiping mechanism that automatically cleans the nozzles before each auto-leveling and start of printing. It integrates waste wiping and collection as well as nozzle cleaning, making this operation even more convenient.

Fully Automatic Leveling Design: The Q1 Pro also revolutionizes manual leveling with a fully automatic leveling design that ensures a perfect first print every time. The principle is based on a dual leveling system. In addition to the proximity switch on the right side of the nozzle, there are three piezoelectric sensors under the hot bed that work together to compensate for Z-axis offsets and complete the automatic leveling.

Remote Monitoring with HD Camera: The Q1 Pro is equipped with a 1080p HD camera that provides users with the ability to monitor the machine remotely, a feature not often seen in machines in its price range. This feature, which is available with the QIDI Slicer software or mobile app, allows users to monitor the progress and status of their prints in real-time, even when they are not at the machine.

If one is looking for a cost-effective FDM 3d printer with active chamber heating and the same print speed and excellent print quality as the MAX3, the Q1 pro totally fulfills your needs. At an introductory price of $469, it represents a valuable investment for both seasoned enthusiasts and newcomers to 3D printing.

Media Contact

Company Name: QIDI Tech

Contact Person: Lexie

Email: Send Email

Phone: 0086-577-66881077

Country: United States

Website: https://qidi3d.com/